3D PRINTING

Working with artists, designers, material scientists and robotics-industry innovators, Parley has developed a range of applications for 3D printing with Ocean Plastic®

To push the boundaries of on-demand material production, we are working with two industry leading partners – Nagami and ABB. Based in Spain, Nagami are 3D printing innovation experts. Together, we created PPE for healthcare workers when the pandemic first started, transforming Parley Ocean Plastic® into protective face shields at rapid speed, equipping the front lines. ABB robotics is the driving force behind the new Parley AIR Station module – allowing individuals and businesses to rapidly design, prototype and build solid structures like public benches, school furniture, community building parts and pretty much anything else.

Printing on demand, Parley AIR Stations allow countries and communities to address marine plastic at source, while reducing carbon emissions from both import and export.

Presented at COP26 in Glasgow, the Parley Blueprint Module is an end-to-end solution for the plastic waste problem on islands and in remote regions, empowering local communities to turn plastic pollution into Parley Ocean Plastic® furniture, objects, building structures and business opportunities. Intercepted marine plastic debris is sorted, cleaned and processed on-site, reducing carbon emissions from the export of waste plastic and the import of finished products from abroad.

“The model showcased at the world stage of COP26 kicks off our vision for an eco-innovative future,” explains Cyrill Gutsch, CEO and Founder of Parley. “We want to empower local communities across the globe by giving them the tools to turn local plastic pollution into business opportunities and useful objects that act as Symbols of Change advocating for the protection of the oceans, the environment and life. Working with two industry leaders, ABB and Nagami, we can now print on demand anywhere in the world to turn a problem into a solution.”

PLASTICITY

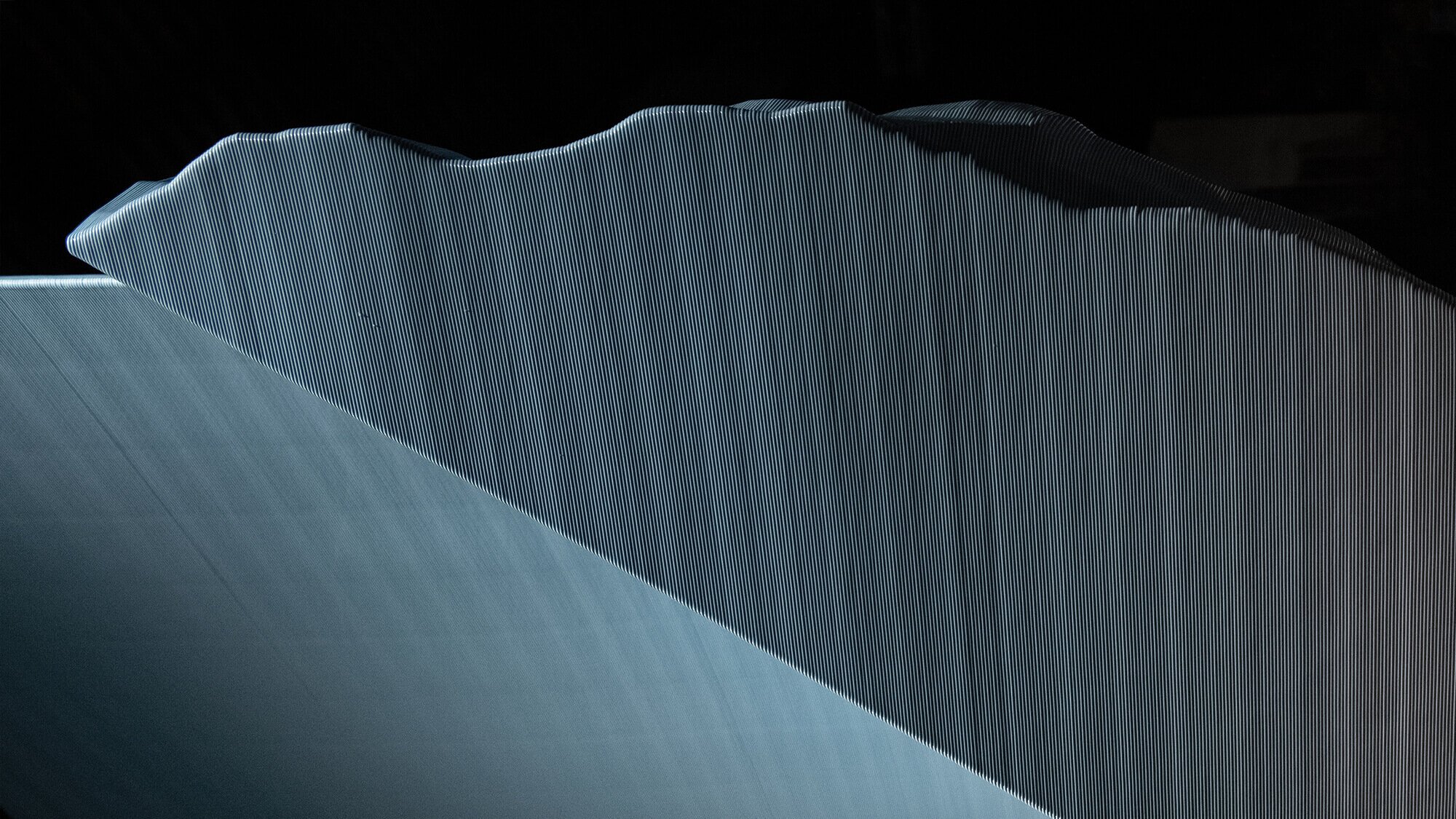

For the 17th International Architecture Exhibition of la Biennale di Venezia, Parley co-presented Plasticity – an installation conceived, designed and constructed by Italian architect Niccolo Casas in collaboration with Nagami and the Italian Pavilion for the prestigious Venice Biennale of Architecture. At 3.6 meters high, it is the largest structure ever to be designed with Parley Ocean Plastic® and was 3D-printed by innovative Spanish design brand Nagami.

“Together with Parley for the Oceans and Nagami,” explains Niccolo, “We are committed to a joint effort with the aim of showing a vision of how architecture can be designed and built in the future but in particular, of how architecture can become an instigator and activator of circular economy. Plasticity is the avant-garde architectural example of what can be done with intercepted plastics from ocean cleaning activities.”

OCEAN PLASTIC® PPE FOR FRONTLINE WORKERS

At the beginning of the pandemic, Parley collaborators Nagami Design worked rapidly to create urgently-needed personal protection gear to help equip frontline health workers. The Spanish 3D printing specialists put their furniture production on hold to focus on supplying hospitals – and were soon printing around 500 protective face shields a day, or one every five minutes. The latest version of the open source shields were created using Ocean Plastic® donated by Parley, and the company’s robots worked around the clock to increase supply.

As Parley founder Cyrill Gutsch commented, "the devastating spread of COVID-19 underscores how interconnected we are as a global community, and as a species within the ecosystem. It also brings into the spotlight the necessity of creativity, collaboration and eco-innovation in overcoming the crises we face. Ocean Plastic® was invented to catalyze change in response to marine plastic pollution and the destruction of our oceans. With Nagami’s technology, we are proud to know our materials will be used to face another existential threat and meet the imperative design challenge of protecting those on the front lines — the healthcare heroes racing to end the novel coronavirus.”

OTHER USES

In 2021, we worked with the British Fashion Council to create their 2021 award trophies and Cannes Lions to create their Sustainable Development Goals Lions from reclaimed fishing nets.

Designed by Jabez Bartlett, the BFC awards were created from Ocean Plastic®, printed in 3D and awarded to each honouree at their 2021 awards at London’s Royal Albert Hall. According to the organizers, “the trophy represents the BFC and Parley’s commitment to encourage positive change within the fashion industry, their efforts to help raise awareness and transparency to promote a more responsible future and encourage the dialogue on environmentally conscious design.”

Parley’s partnership with Cannes Lions, meanwhile, saw reclaimed polyamide fishing nets – a key threat to life in the oceans – transformed into the iconic Lion trophies. Speaking about the partnership, Philip Thomas, Chairman, LIONS, said “this award has always been about celebrating the organizations that are taking action to promote good in the world and drive initiatives that positively impact and enhance the lives of the global community. It’s only right that the trophy - the physical symbol of change-driving creativity - reflects this too. Parley’s approach to addressing the threats to our oceans is truly innovative and creative. We can’t wait to hand over these unique, and rather special Lions to the worthy winners.”