PARLEY X BIOFABRICATE

Parley’s ongoing collaboration with Biofabricate explores the future of grown materials

From banana fibres to protein brewing, the latest Biofabricate summit presented a leading line up of speakers and showcased bio-based solutions changing design as we know it. A nexus of designers, scientists, startups and brands, the event has created a new community of pioneers working for for the planet. Sharing our vision to end the era of toxic materials, Parley partnered with Biofabricate for the third year running, bringing the New York based summit to Europe for the first time.

Kicking off the event, Biofabricate founder Suzanne Lee and Parley founder Cyrill Gutsch highlighted the urgency of developing new material alternatives to plastic, underlining a deadline of 2030 as the point-of-no-return for our oceans. We need a material revolution now, and the Biofabrication movement that Suzanne has inspired lies at the very core of the strategy needed.

One of only 50 Moon Parka jackets produced with Spiber’s brewed protein fiber – a biodegrable material that mimics spider silk.

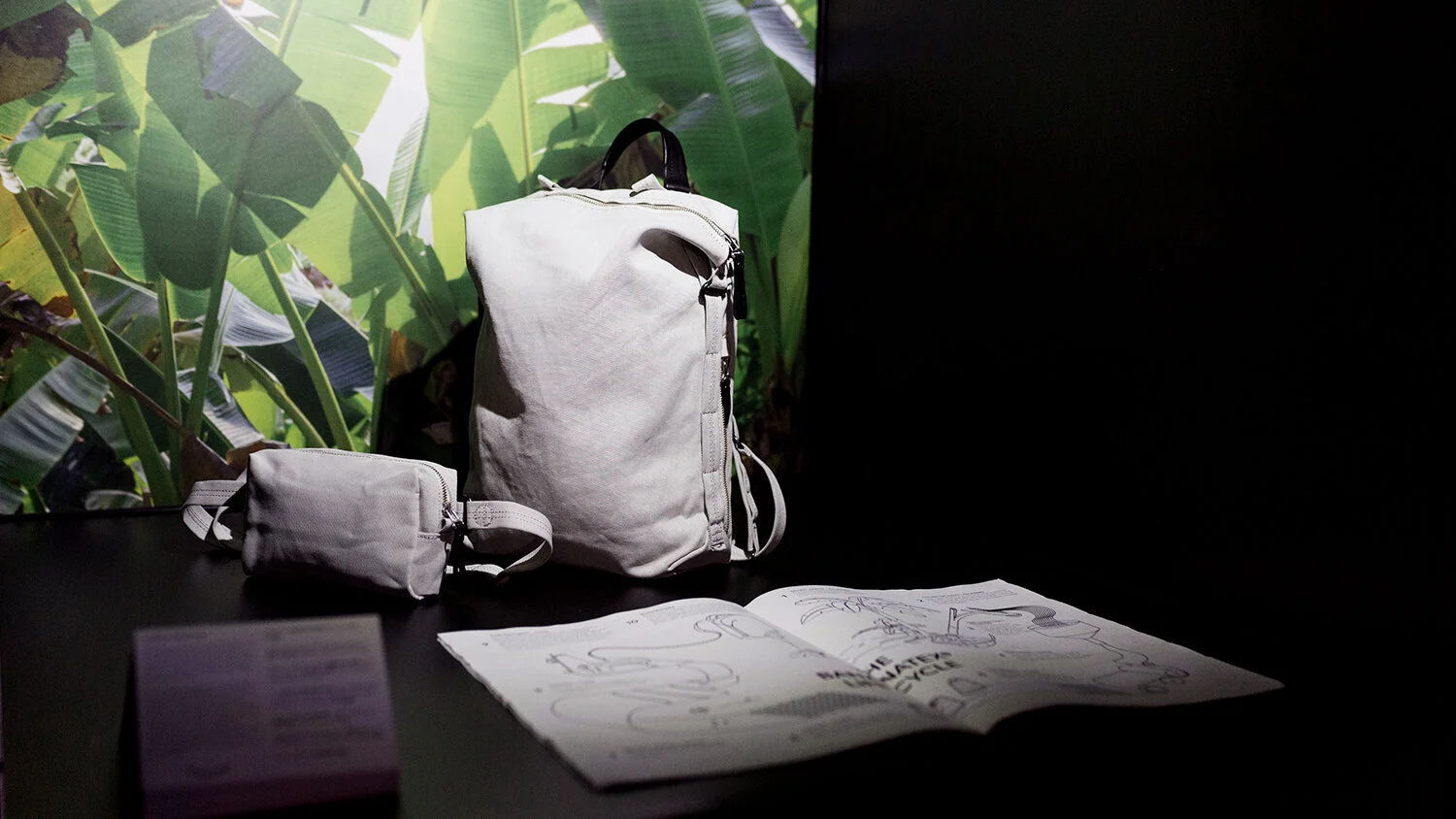

Three years in the making, BANANATEX™ is the world’s first durable, waterproof fabric made purely from banana plants.

One of the major challenges faced by biofabricators and material scientists is time – something our planet is rapidly running out of. This theme emerged throughout the day as speakers presented development timelines that ranged from three to over ten years. After a challenging four-year development process filled with trial and error, Kenji Higashi of Spiber presented the much-coveted Moon Parka – created with a brewed protein fiber mimicking spiders’ silk.

The project was initially projected to take one year but the material took on a property found in spiders’ silk called supercontraction, causing the fabric to shrink by up to 50% when water is absorbed. Following this setback, an enhanced version of the proteins were then created for the coat, redesigned using gene-editing techniques to provide only the desired properties.

Creating yarns from kelp, AlgiKnit showcased their rapidly degradable fabric solution for the fashion industry.

Biofabricate’s lanyards and nametags were produced from non-toxic materials and will be used again next year.

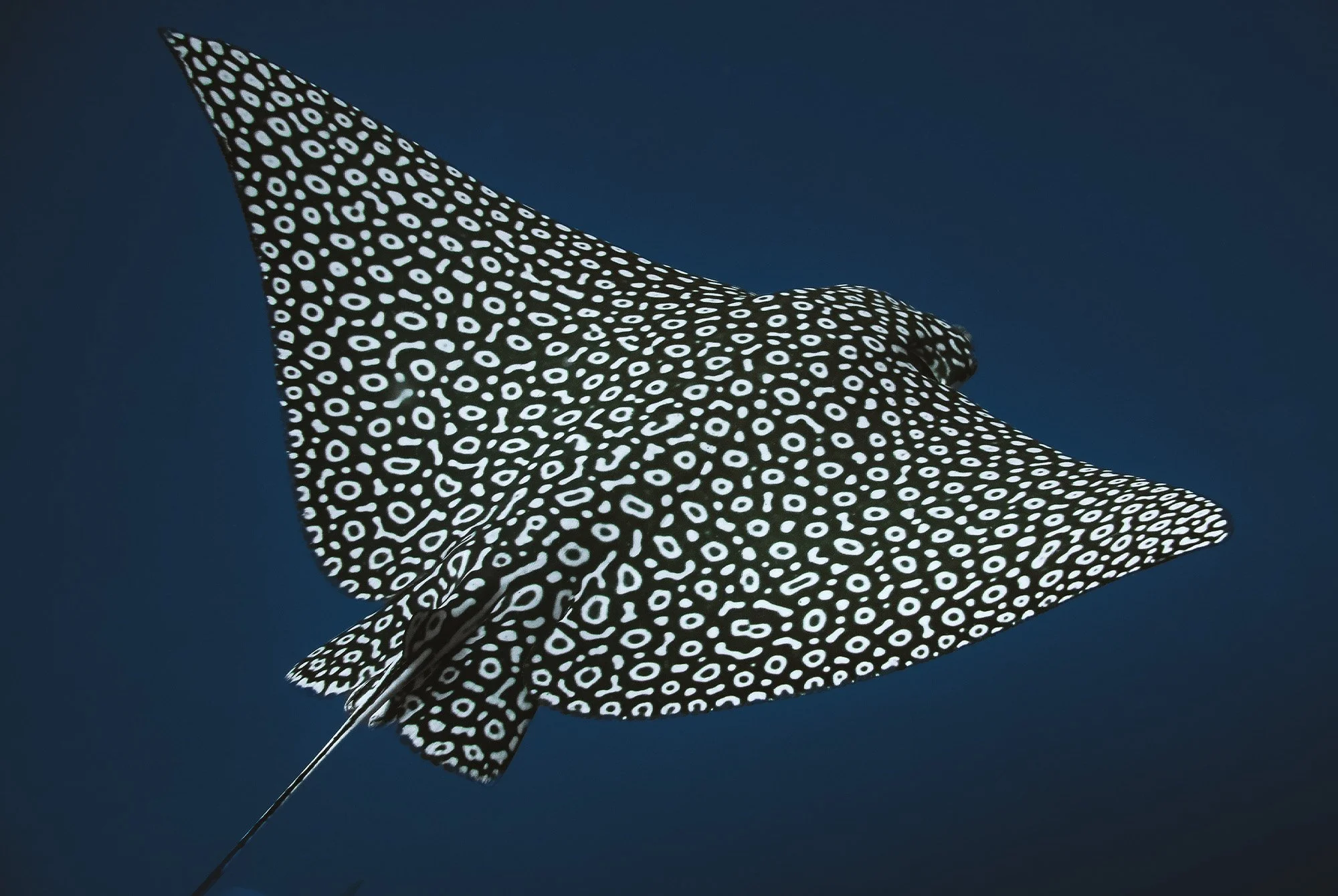

Taking their inspiration from the sea, bioMASON grow materials for the construction industry using the natural process of calcification observed by founder Ginger Krieg Dosier in coral reefs. The traditional production of bricks by firing in a kiln releases a range of pollutants with the industry emitting 800 million tons of CO2 each year. In contrast, bioMASON grow their bricks at room temperature using bacterial byproduct to cement sand particles together eliminating CO2 emissions as well as any manufacturing waste that pollutes our waters.

Plastic, used all too commonly in interior design, is a design flaw and needs to go. After years of exploring the potential of mycelium-based technologies, MOGU presented a full catalogue of products for interior design application. An example of how an industry can be disrupted when biofabricated material come to market, MOGU offers today the first commercial mycelium-based products on the market.

With 2030 now only a decade away, can we get such biomaterials out into the real world at a large enough scale to help save it? Some good news on that front – the 2019 summit saw more biofabricated materials than ever before come to market. The change is being accelerated by bio-based companies rapidly developing their ability to scale. In the last year, silk-based microcapsules produced by AMSilk have been used in over 20 million cosmetic products instead of the plastic microbeads that have wreaked havoc on our seas and marine life.

"Both Parley and Biofabricate believe the next generation of material innovation must be better than the last. Together we are trying to create a new material revolution.”

Suzanne Lee — CEO & Founder, Biofabricate