How Spiber are Studying Spider Webs and Using Biology to Replace Fossil Fuels

We speak with Kenji Higashi about material innovation, the fashion industry and the importance of circularity

At Parley, we’re always thinking about the future. What can the world look like? How can it be improved? How can we not just live in harmony with nature, but learn from it? We are aware that we cannot simply recycle our way out of the plastic crisis – we need to redesign the structures and systems that pollute our planet, along with the harmful materials that we’ve become addicted to. It’s why we’re calling for a Material Revolution – we have to change the way we make things in order to create the future. In this ongoing Parley series we meet the innovators, scientists and start-ups who are reshaping our material world.

Spider webs have long occupied a place in human consciousness as objects of natural beauty, stunning feats of engineering, works of art that are depicted in our storytelling and mythology across cultures over thousands of years. Gram for gram, most spider silk is five times stronger than steel, and it’s even been suggested that if human-sized it’d be able to stop a Boeing 747 mid-flight.

Spiber is a biotech company founded in 2007 in Tsuruoka City, Yamagata, Japan, by students who were fascinated by the concept of using biology to help eradicate our reliance on fossil fuels. After learning about how spiders make incredibly tough materials their early experiments focused on arachnids, hence the company name. In the 18 years since they formed they’ve developed their own range of fibers called Brewed Protein™, created using their fermentation technology, with the result being biobased, biodegradable materials.

Over the past decade, Spiber’s Brewed Protein™ has begun to spin its way into fashion, with the company’s materials appearing in apparel made by major player fashion brands such as The North Face and Junya Watanabe, Woolrich and Iris Van Herpen. After spending some time at this year’s Biofab Fair with Kenji Higashi, Spiber’s Executive VP of Sustainability, talking about material innovation, we thought it a good time for an in-depth interview about their work so far, along with a look into the future.

Q&A

Spiber was founded in 2007 – what was the motivation behind the formation of the company? What was the specific problem that you identified and the opportunity and solution that you saw?

Kenji: I studied bioinformatics at Keio University in the same lab as Kazuhide and Junichi, who founded Spiber. I joined the team some years later, but as graduate students we were focused on the problem of the world relying on fossil resources, which are limited. We saw a huge opportunity for biology to help solve this problem. We were really fascinated when we learned about how spiders make really tough materials. The fibers that they make are said to be the toughest materials known in the world. These are made by these little insects or spiders who just eat and process proteins into these super tough fibers, which is so interesting. So we decided to see if we could apply this “super material” that’s been made by nature to industrial applications and try to find ways for the world to move away from relying on fossil resources.

What else do you find so inspiring about that material and what are its other unique properties?

It's such tough, amazing material, made by these little living things. It's made without any solvents or any extreme temperatures or pressures. It's all in the living organisms – they just form these amazing fibers and spin them out on demand. They can turn it on and turn it off, like a faucet. It’s fascinating how something like that can happen, but it really comes from a very, very long history of evolution that lets these spiders have these amazing properties. However, there were challenges when trying to use these fibers for industrial applications. When we first succeeded in making enough fiber to make a garment we made one with Goldwin, one of our earliest partners, who own The North Face in Japan. They made a garment using our fibers but when it got wet it shrank dramatically and we learned that this is also a functionality that spiders have gained through evolution. When it rains, if it shrinks, then less water will adhere and it can help protect the integrity of the web. It's a fascinating material.

Did you have to study spiders closely in the lab?

We used to go out and catch spiders, take their silks and release them. Many years ago we also had some spiders that we kept like pets. However, since we learned around 2016 that simply replicating spiders was not going to get us the materials we need, we realized that we needed to change the design of our protein. Since then, we've shifted away from trying to replicate spider silks towards trying to make protein materials that work for the end applications. Now, we don't need to be studying spiders every day.

How do you think Brewed Protein can radically change and revolutionize the fashion industry and which particular harmful materials you see it replacing?

We started out trying to copy spider silks, trying to replicate the amino acid sequence that makes up spider silk proteins. Now we're creating different protein designs and we've made thousands of different variations, but we can design for different types of properties, different types of performance. The main fibers that we are producing today are most similar to animal fibers like silk, wool or cashmere. Animal fibers require a lot of resources and animals release greenhouse gases from their bodies. I wouldn't say that we're going to replace everything, but if a brand was going to consider using animal fibers, they could also consider using our fibers instead. We're also trying to develop new types of materials that are not simply proteins, but modified protein polymers that perform more like synthetics. For example, stretchy fibers that could perform somewhat like polyurethane or more hydrophobic polymers that could perform somewhat like nylon or polyester.

In terms of environmental impact, how does Brewed Protein outperform its toxic counterparts?

Animal fibers require a lot of land and resources. You can either let them graze on vast grasslands or you can feed them grains or hay. Grains and hay also take lots of land, fertilizer and energy to produce. We do require some sugars to make our fibers, but just to give a sense of scale, it’s said that to make one kilogram of cashmere fiber, you need roughly about four goats and it takes them about a year to make. Each goat eats hundreds of kilograms throughout the year. For our fermentation it takes us around five or ten kilograms of sugar to make a kilogram of protein fiber. There are two different routes to make protein fiber but there's a vast difference in the amount of resources that are required. Also, synthetics often don't degrade at their end of life whereas our fibers are protein, so they will be broken down.

Can you explain a little bit more about exactly how you create Brewed Protein?

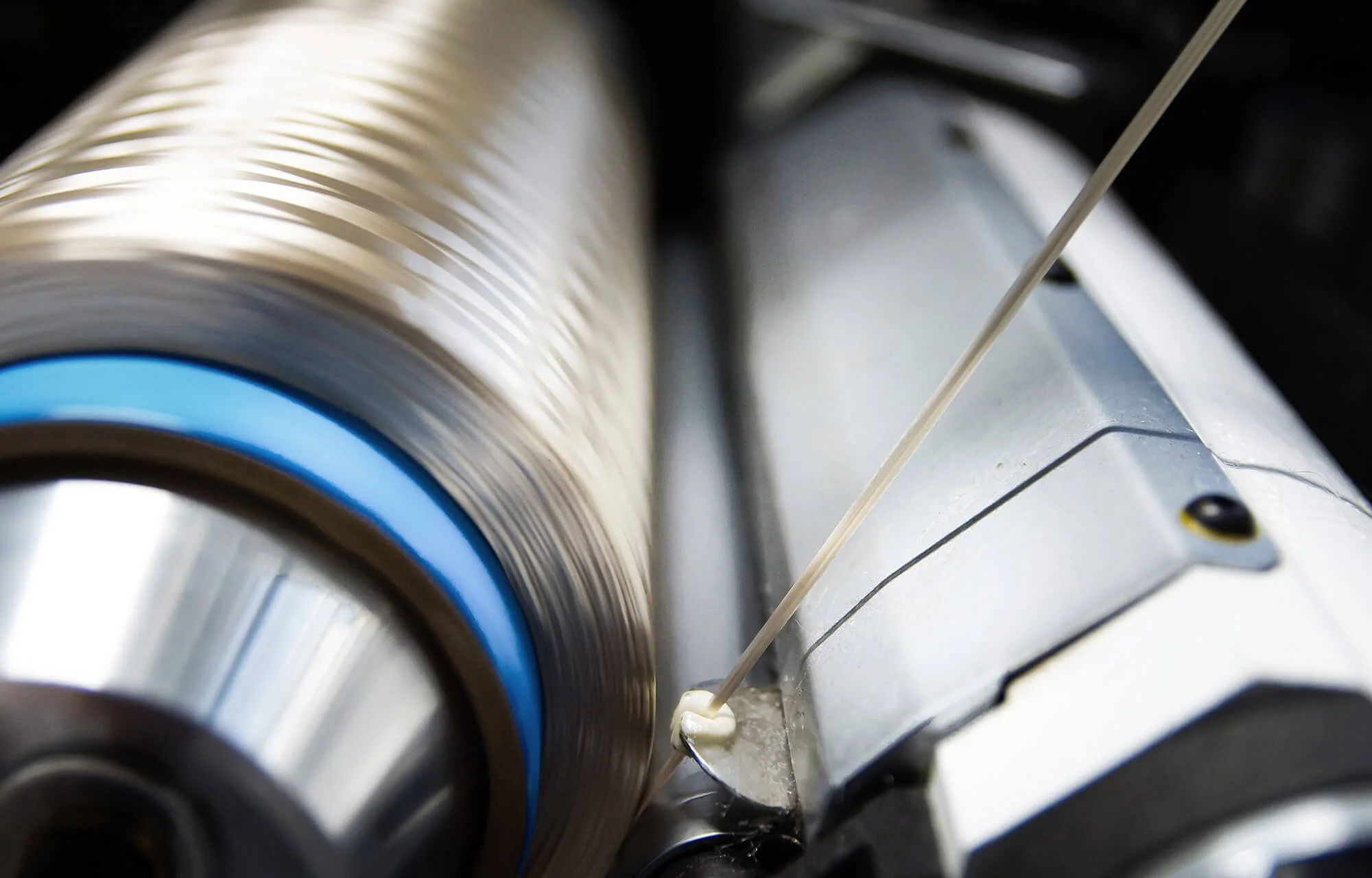

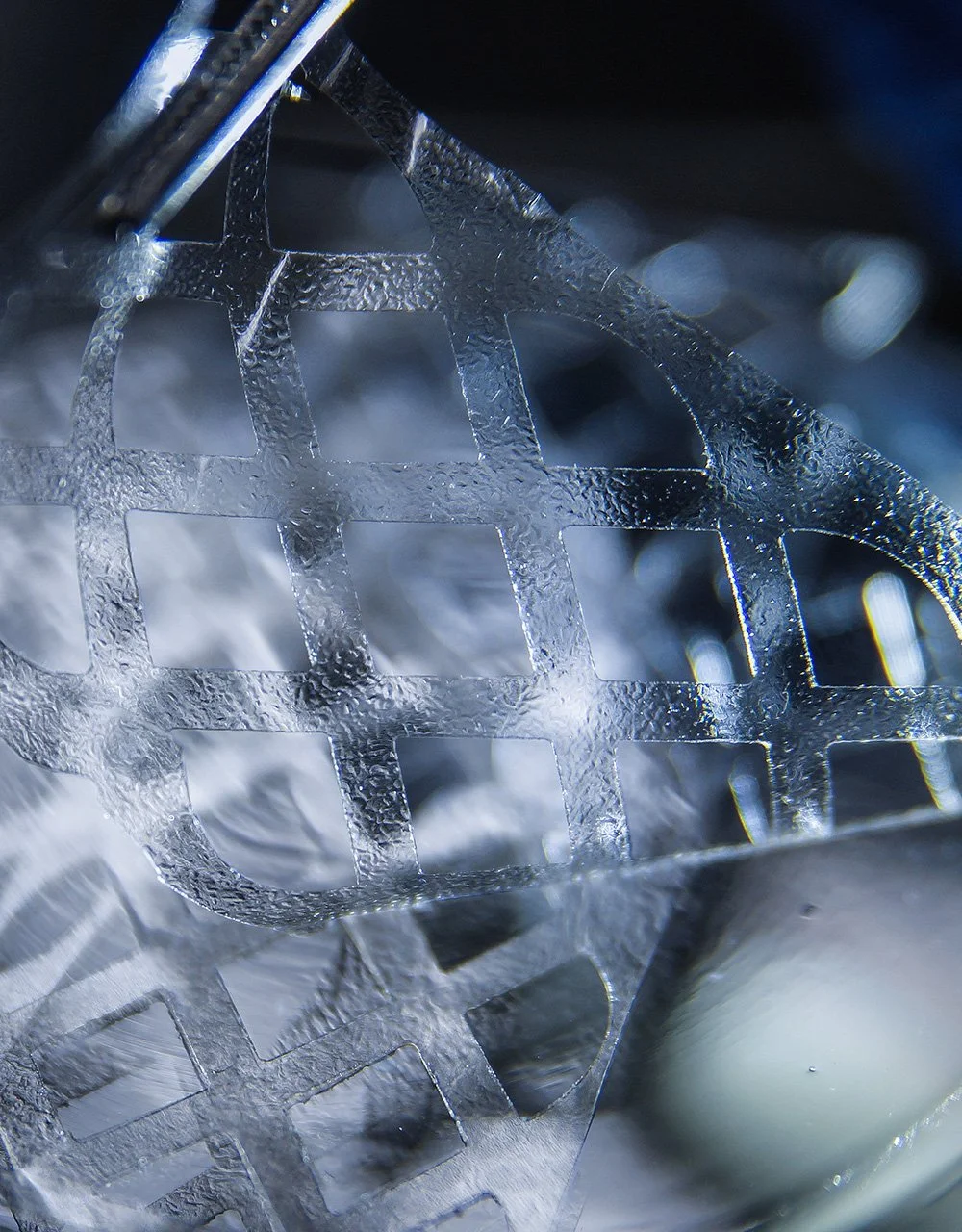

First of all, we design the proteins by studying living things like spiders, silk worms or goats and sheep. We study their DNA and look at the proteins or the fibers that they produce and study their properties. We use that knowledge to create our custom protein designs. Then, we synthesize the DNA that corresponds to those protein designs and we put them into our microbes for fermentation. We put these microbes into big tanks for fermentation, where we are essentially giving the microbes sugars and some other nutrients that they need, so that the microbes will eat and will produce protein. It's like a beer factory, but instead of making alcohol, our microbes make protein polymers. We purify those polymers, dissolve them into a solution and push them through a nozzle with lots of small holes, and the polymers come out of the nozzle and solidify into fibers. We chop those fibers up and they can be spun into yarns to make garments.

Fiber Fluff

Spun yarn

Spun fabric

Leather

Film

Resin

“There are two different routes to make protein fiber but there's A vast difference in the amount of resources that are required.”

Kenji Higashi — Executive VP of Sustainability, Spiber

How excited do you perceive the fashion industry to be to introduce all these new biomaterials to their supply chains and to their customers? Does it really require the backing, the interest (and maybe some profit loss) of the fashion industry in order to drive this change?

It's a great and very important question. Some of our partner companies are very excited and that's why they have taken risks at these early stages to work with our materials and try to figure out how they can actually use them. So there is definitely a lot of excitement from certain companies, but what we really need is to make it mainstream. We need the largest companies that use the largest volumes to be excited about using it, even if it's a bit more expensive, or help us scale so that we can bring the cost of materials down enough so that it makes sense for them. It's been a challenge for us to be able to figure out how we can scale so that it makes sense for the big players. I think some of the policies that the European Union is putting in place are really trying to drive the adoption of more sustainable, circular, lower footprint materials. These policies aren't yet fully developed, fully announced, or fully in effect, but I’m looking forward to a time when it’s more economically feasible for large brands to use these types of new materials.

How crucial do you think a reimagining of our material world is to helping us to avert the climate crisis?

I think it's very important. Finding circular solutions is especially important. I'm really excited about the prospect of being able to use agricultural, textile waste or any other biological wastes as a feedstock. I think there's potential to shift industries away from petrochemical-based production towards bio-based production. I think that there's huge potential to replace a lot of the petrochemical based solutions that are currently mainstream.

Is there an industry that Spiber isn't currently working in that you feel like it should, or could?

Yes. Most of the customers that we have worked with up until now are mostly apparel and textiles, but there's other types of textiles used in the home, or for interiors and cars. So I think there's lots of potential in those industries for fiber and textile applications. We're also developing films and membranes that can replace polyurethane or PTFE coating on fabrics. When you put those materials on a fabric, it's very difficult to recycle it. We are hoping that we can use our polymers to replace synthetic ones in order to make membrane layers and coatings for textile applications. Another interesting project that we have is for food and meat. Often, alternative meat is usually made from things like beans or peas, usually in a hamburger or minced meat format, but steak meat is difficult to make. Steak is muscle structure and muscles are essentially bundles of fiber. We are able to use our protein fibers and use them to give texture to alternative meats to give them a similar feel. However, that's another project that’s also not yet commercial and still in development.

What are you most proud of about your work at Spiber and where do you see yourselves in ten years?

I'm really proud of how our team over the course of two decades has been able to transform something that was 20 years ago a fantasy or fiction to make protein from a lab-grown process, but we've made that into a commercial-level reality. Plus, we can do it at a cost that makes sense commercially and with an environmental footprint that is beneficial compared to alternatives. What's really amazing is the productivity that we've achieved and being able to make proteins super efficiently is what we've achieved over the past two decades. Now, I think we're in a position to make this mainstream. I hope that in ten years we can scale to a level where we can make a real dent in the industry's carbon footprint, and also make a real dent in enabling circular manufacturing for the textile industry and beyond.